The automotive industry is undergoing a revolution, as electric vehicles (EVs) rapidly become a popular choice for consumers seeking affordable and eco-friendly transportation. One crucial aspect of EVs is their power electronics, which are responsible for converting the direct current (DC) from the battery into alternating current (AC) to power the motor. The execution of these electronics, specifically the converter, has a significant impact on the overall output of the EV. In recent years, there has been a growing interest in using wide bandgap (WBG) devices in EV converters due to their superior performance compared to traditional silicon-based devices.

Traditionally, silicon-based devices, MOSFETs and IGBTs, have been used in EV converters due to their maturity and reliability. However, these devices have limitations in terms of switching speed and power density, which can restrict the efficiency of the converter. WBG devices, such as silicon carbide (SiC) and gallium nitride (GaN) transistors, have superior characteristics such as higher breakdown voltage, faster switching speed, and lower on-resistance compared to silicon-based devices. GaN E-HEMT cascode and SiC trench MOSFET are two such WBG devices that hold great promise for further improving the converter's efficiency.

Ⅰ. An Overview of Wide Bandgap Devices

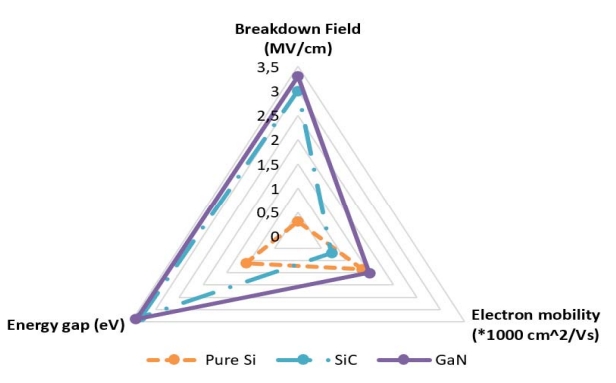

The use of GaN and SiC has gained attention as the "next generation of semiconductor devices." They have a wider band than conventional Si, as shown in Figure 1, which also displays their mapping characteristics and clarifies why they are known as "WBG Semiconductors." A cascode structure involving a low-voltage Si MOSFET with GaN-HEMT has been developed to ease the process of turning on the device. This technology has been tested on two commercial devices, resulting in improved performance and cost-effectiveness when compared to silicon-based transistors.

Figure 1 Bands of Si, SiC, and GaN.

Market researchers project that the WBG power semiconductor market will grow at a rate of 17 in the next 10 years. This is due to the growing demand for power supplies, hybrid and electric vehicles, photovoltaic inverters, and other established applications. The dynamic capabilities of 650-V cascode GaN power devices have been evaluated, showing great potential for enhancing the performance and efficiency of converters.

Ⅱ. Operating Principle of Wide Bandgap Devices with Case Study

During the experiment, the primary component used to process inputs was a GaN E-HEMT switch. The integration of inputs was achieved by using a GaN-HEMT cascode configuration with a normally-OFF LV Si MOSFET and a normally-ON HV GaN-HEMT. The devices' on-resistance was added together when both are on, but the bias voltage is sustained when the Si-FET gate was turned OFF until it reaches the pinch-off voltage of the GaN-HEMT, which turns the HEMT off. The combined device is normally-OFF with a gate threshold of the Si MOSFET and a blocking voltage equal to the GaN-HEMT gate–drain breakdown voltage. An appropriate Si MOSFET with a breakdown voltage greater than 25 V and on-state resistance smaller than the GaN-HEMT resistance can be used for this configuration.

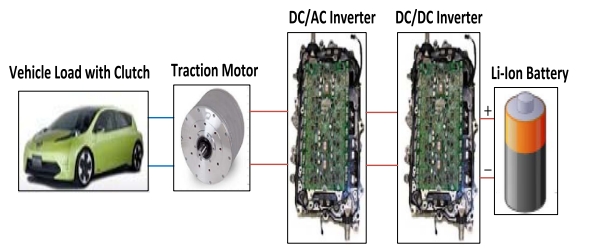

A PSIM software simulation was conducted to create a model, which included an 80-kW AC synchronous motor, a 24-kWh/360 V lithium-ion battery with a nominal rating, and a load torque of 200 N/m. Figure 2 shows the EV powertrain models simulated on PSIM using the below formulas:

Equation 1

Equation 2

Figure 2 Block Diagram of the Proposed System.

Ⅲ. Components Used During Modelling

The simulation model consists of several components, including a constant torque load with a clutch that represents the vehicle load. This load remains independent of speed and any deviation from the value can cause undesired tire movements. An interior PMSM block was utilized in the NLEV PSIM model to represent the traction motor. Due to its high saliency, this type of motor can offer a wide field weakening range, making it an optimal choice for EV applications.

The EV dc-dc converter is a bidirectional drive that was placed between the HV battery and the motor drive. It can operate in both motoring (traction) and regenerative braking modes. The DC-DC converter control uses a PI control method to switch the converter's transistors and adjust the firing signals according to the mode of operation, whether it's charging or discharging the battery. It consists of a charge controller, discharge controller, and regeneration controller.

Lastly, the NLEV PSIM model employed a three-phase voltage source inverter for the traction motor which utilizes speed and DTC controls for torque reference and maximum torque per ampere control. Beyond a threshold speed, the motor operates in the field weakening control, and the DTC block limits the torque reference accordingly.

Ⅳ. Analysing the System Performance

The power train model was evaluated using pure silicon, GaN, and SiC at different switching frequencies. At 50 kHz, the total switch power losses in Watts for the GaN-HEMT cascade are 183 W, which is significantly lower than the pure Si MOSFET of 1080 W. At high frequencies, GaN total losses are only 2.45% of the power converted compared to 2.7% for pure Si at 50 kHz. The GaN-HEMT cascade was found to be much more efficient than the SiC trench, where the loss of load power for GaN and SiC is 0.457% and 0.675%, respectively, at 50 kHz.

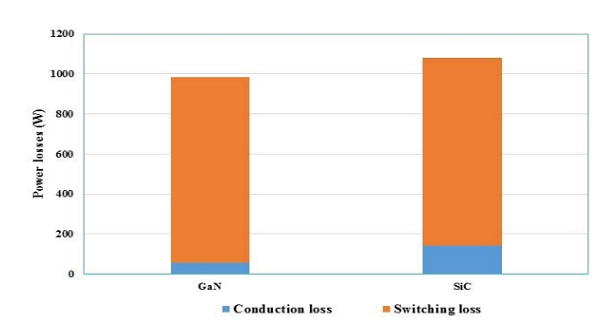

Figure 3 Switch loss contributions in watts for GaN and SiC at 400 kHz.

Figure 3 shows the switch loss division between different loss sources at 400 kHz for the GaN-HEMT cascode and SiC trench. The gap between GaN-HEMT cascode and SiC trench is wider at low frequencies, where the switching loss becomes less dominant. The conduction loss of GaN is also found to be less than that of the counterpart SiC trench MOSFET.

Ⅴ. Simulation Results

Tests were conducted to evaluate the performance of GaN-HEMT cascode and SiC ACCUFET in terms of higher efficiency and higher switching frequency. The laboratory-tested system showed that the GaN switch can achieve a stable efficiency of around 98.7% at 100 kHz switching frequency, while SiC ACCUFET can record the same efficiency while switching only at 40 kHz. This GaN record efficiency is stable with different switch loading percentages, which demonstrates the superior efficiency of the GaN-HEMT cascode.

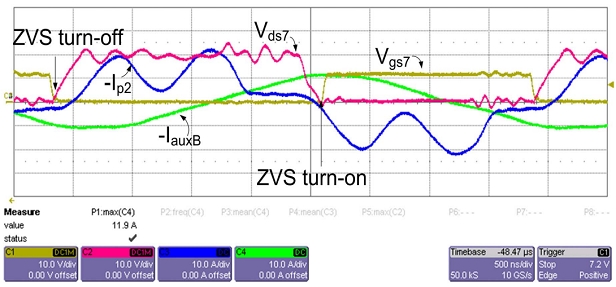

Figure 4 Turn off and turn on time of ZVS inverter.

The results are consistent with the simulation results in Figure 4, which shows the inverter circuit waveforms. The waveforms reveal that zero voltage switching (ZVS) occurs in both turn-ON and turn-OFF instants, reducing the total power losses by eliminating the switching losses of the inverter switches. Additionally, ripple reduction in voltage/current waves was achieved by using DV/DT filters, DTC methodology, and an inverter motor control loop. These techniques further improve the performance of GaN-HEMT cascode and SiC ACCUFET by reducing power losses and improving overall efficiency.

Ⅵ. Conclusion

When it comes to EVs, efficiency is a key factor to consider and the use of fast-switching GaN and SiC semiconductors can significantly reduce switching power losses and allow for high-frequency operation. Through experimentation and simulation, it was found that the total switch loss for GaN E-HEMT cascode is 2.45% at high switching frequencies, which is lower than the 2.7% of the SiC trench. Additionally, the efficiency margin between SiC and GaN switches remained relatively constant at 0.6%–0.7% for all normal load cases tested.

Switching WBG devices at 300 kHz achieves current and voltage ripple reduction, fewer passive elements, and magnetic circuit volume, improving power density and mileage. Moreover, higher switching frequency reduces converter footprint and weight by 30%, resulting in less energy consumption and higher mileage.

-

Tel

13824346118 -

Whatsapp

ENGLISH

ENGLISH 简体中文

简体中文